Custom Wave Tags

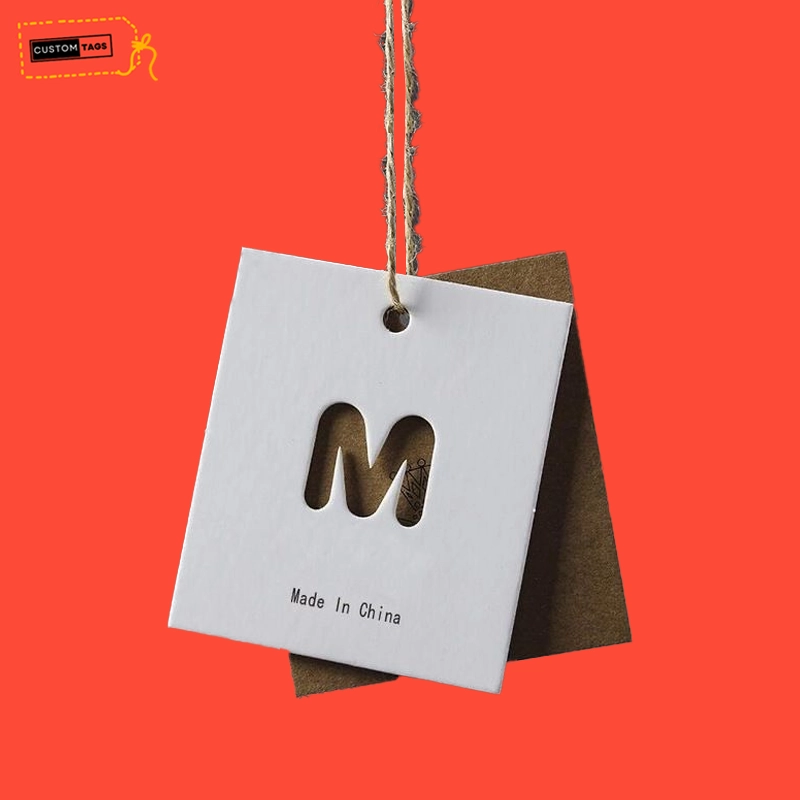

Tags are the complementary items that show important information about the product and will enhance the beauty of the products. Discover a world of possibilities with custom wave tags that set your products apart. Now TheCustomTags bring catchy and trendy tags with logos to help to showcase the brand value.

We provide a range of sizes and styles with quality material and printing. We offer kraft, cardboard, and chipboard materials that are favorable to printing. Our eco-friendly tags help to enhance the brand visibility. We provide skill matt coating, and glossy finishing to add a luxurious touch to your products.

Choose us for your customized wave tags because we provide affordable prices without compromising on quality. Our fast production helps to manage your inventory. We provide free design assistance from our experts. Order now and elevate your product presentation.

The use of wave hang tags has increased at a very large scale in recent years. This is mainly due to the wide range of benefits these tags provide. Brands use tags to give an identity to their products and win customers’ trust. At our company, these tags are manufactured with premium quality materials. This makes it easy for the companies to show why their product matters.

You can opt for multiple designs and custom artwork on the tags to give an identity of your company. The wave shape of the tags gives a unique appearance and grabs customers’ attention. There are unlimited options for custom tags in the UK at our company that you can choose from and decorate your product.

What Is A Wave Hang Tag

A custom wave tag is basically a product label that uses curvy edges instead of the usual boring straight lines to grab attention. These tags act as marketing tools for businesses and help them to grab the attention of their target audience in a crowded market. Wave tags offer an excellent, attractive appearance along with space for adding important information related to the product. These tags also help businesses to create a lasting impression on their customers and ensure repeat purchases.

Manufacturing Process Of Our Custom Hang Tags

We use advanced manufacturing processes and machinery for our custom wave hang tags. Our experts monitor every step of production very closely to avoid mistakes. Moreover, the use of AI technology in machinery reduces the chance of further micro mistakes. The manufacturing process of these tags depends upon several steps. Such as

Design And Prepress

This is the very initial and the most important step of creating a Custom Printed Wave Bags. Our designers use specialized software to create a digital print of your actual tags that will be manufactured. To avoid any mistakes and misprints, these digital copies are sent to clients for confirmation. With their years of experience, designers make sure that every digital print is free from any flaws and can be used as a base for printing. This selected design is then sent to the press section, where it is used in a very specialized way to print multiple gift tags on a single sheet without any flaw. A high-resolution plate is then generated with the help of computer-to-plate technology.

The Selection Of Material

The second process of Wave Name Tag manufacturing is the selection of material, which is also considered the most important step. We gave our consumers a variety of material options so that they can choose any of them according to their specific needs. Each material offers its unique benefits and qualities that make it different from others. We offer many types of material options such as.

- Premium Cardstock

- Recycled Kraft Paper

- Synthetic Plastic/Vinyl

- leather

Use Of Printing

In this process the several brand elements are used to make Wave Hang Tags Printing a marketing tool for your business. This can be used for the placement of logos or your brand name. Some other more prominent factors can also be included on your tags. We use specialized printing machinery for this process. This method is done by using two main methods of printing.

Offset Printing

This method is commonly used for large orders where thousands of bulk orders of Wave tags at wholesale need to be done. In this process, physical metal plates and large ink rollers are used for different prints. It makes a consistent colour with high accuracy, helping to define brand colour.

Digital Printing

For small production where every single tag needs its own unique detail, this printing method is used. It works much like a high-end office printer but produces excellent quality Wave Tags with a logo, with faster setup times.

Applying Finishes

Digital Foil is also a popular method that allows metallic effects on short-run digital orders without the need for custom metal dies. The use of finishes helps brands to add a luxurious look to their tags. It makes your Kraft wave tags more attractive and helps brands to justify their increasing prices. We offer various kinds of finish options. Such as

- Lamination: A thin film of plastic is applied to the surface of custom tags. This not only protects the ink from scratching but also adds structural integrity to the wavy edges and prevents fading.

- Foil Stamping: A metallic foil is added to the surface of custom wave tags UK by using heat and pressure. It is available in many different shades.

- Embossing and Debossing: Metal dies are used to physically reshape the paper fibres. It creates raised or recessed patterns. This adds a 3D tactile element that encourages customers to touch and interact with the circular hang tag.

Use Of Die-Cutting Machinery

Die-cutting is used to transform a standard sheet of paper into a unique shape, wave tags with no minimum. These printed sheets are fed into a die-cutting press that uses pressure to create a wave shape. Laser Cutting is used for highly intricate wave designs or very small batches. It offers extreme precision without the need for physical dies.

Hole Punching And Stringing

TheCustomTags that come with a string are called Wave Name Tags with string. It is the final step some machines use to create a hole at the top of tags and a string. This helps these tags attach to products easily.

Fetch Us Today!

We are providing our customers with the best quality custom wave hang tags. Our experts have years of experience in ten packaging industries. They make sure that the tags you get truly represent your thoughts. We assist our customers in creating tags that provide both functionality and visual aesthetic at the same time. Get in touch with us today and place your order. For more information, visit our website today.

What is your MOQ for custom tags?

The minimum order quantity for our custom tags is 1000 per order. You can also contact our customer support team to get more information.

What should I do if I receive damaged goods?

In case of receiving damage or the wrong product. You have to immediately contact our customer support team. Your team helps get through this situation as soon as possible.

Can I get a sample before production?

Yes, we offer our clients a sample of their selected packaging. This not only helps clients to understand how the product will turn out but also reduces the chances of future problems.

Are your tags durable?

Yes, we use high-quality material in the manufacturing of our tags. This makes our tags more durable and tear-resistant.

Where can I place my order?

You can visit our website to place your order. Consumers can also contact the customer care team to get information about the ordering process.

Our Services

Our Services

Professional Printing Services

Get your tags designed impeccably, professionally, and uniquely

Branding Elements

We print your brand specifications on tags, making them an efficient promotional tool.

Product Information

Mention necessary information and tell your customers how to handle, store, and wash the product.

Unique Shapes And Design

Incorporate your brand’s aesthetics and shapes that signify your theme and showcase your brand values.

QR Codes

Halt any kind of counterfeiting attempt, make payment easy, and inventory managemnst convenient with our QR code printed labels such as micro embosisng.